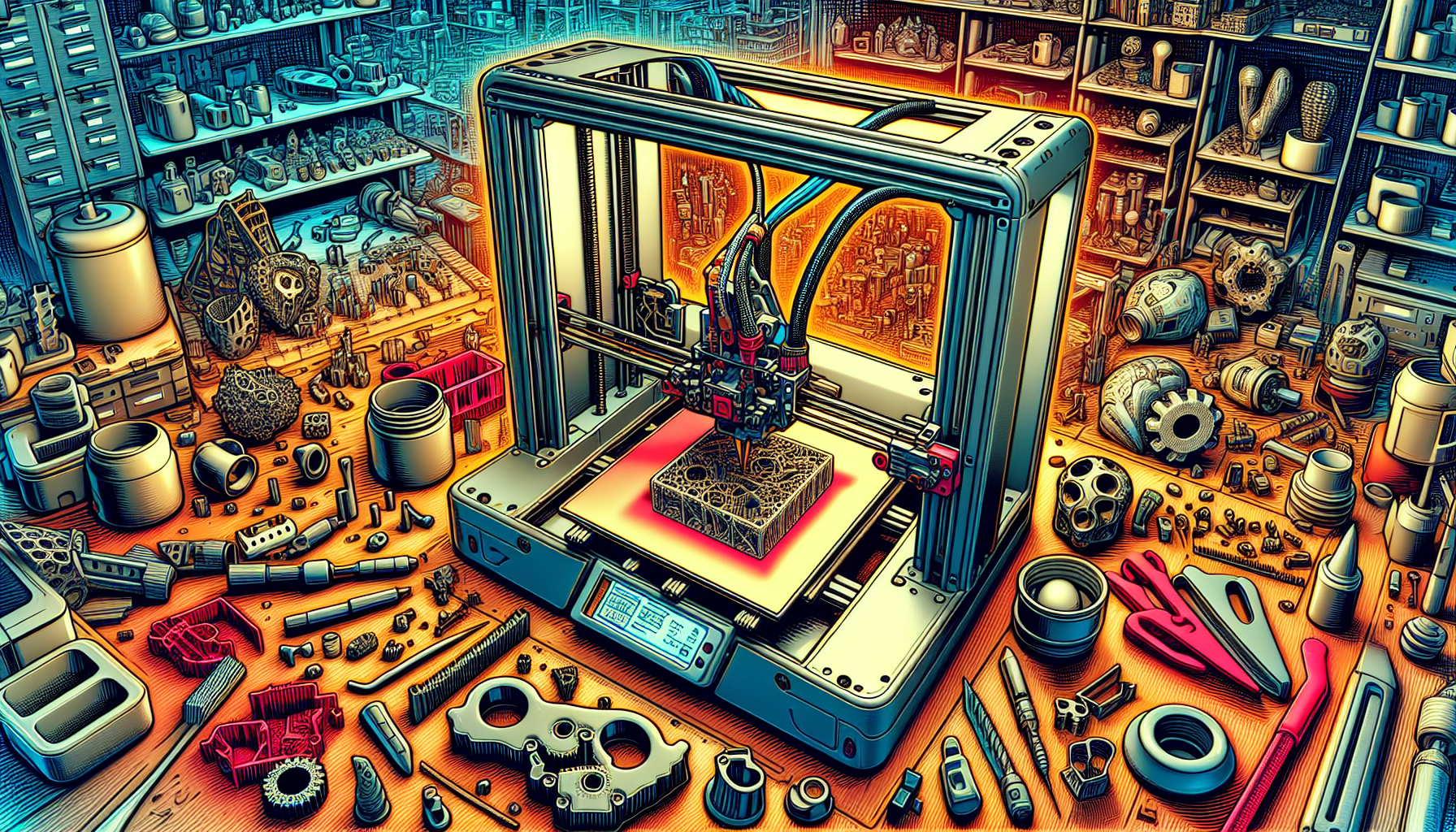

Since its inception, 3D printing has taken the world by storm, changing how we create and innovate across various industries. From the early days of printing simple plastic models to today’s intricate designs, advancements in materials have always been at the heart of this evolution. Enter silicone filament, the newest player unveiled by Filament2 at Formnext 2024. This exciting material promises to open new doors for both makers and professionals.

![]()

The arrival of silicone filament is nothing short of a revolution in 3D printing, altering our perception of what this technology can offer. Known for its unparalleled flexibility, heat resistance, and durability, silicone caters to those in need of robust and adaptable prototypes. Unlike previous materials that typically required specialized, expensive equipment, this new filament works seamlessly with standard FDM 3D printers. The result? An easier process that allows more people to dive into silicone-based printing. Just imagine, you’re no longer tethered to bulky machinery when you want to produce intricate designs; it’s almost like having a magic wand in your arsenal. With silicone filament, you can create designs that stretch, bend, and remain intact under pressure. The flexibility it offers can change how prototypes are made and tested, pushing the boundaries of creativity and functionality.

The potential applications for silicone filament are virtually limitless, and many sectors stand to gain significantly from this breakthrough. Those in the medical field can benefit greatly. Silicone’s biocompatibility makes it perfect for custom parts in implants and prosthetics, tailored to each patient’s unique needs. Picture a future where surgical tools are as flexible as the procedures they assist, minimizing friction both in crafting and implementation. Meanwhile, the automotive industry isn’t left behind. In a world constantly seeking greater efficiency, silicone filament allows manufacturers to produce heat-resistant gaskets and seals right in-house, streamlining production like never before. This not only slashes lead times but empowers design experimentation without the typical constraints of resources. Consumer electronics manufacturers are also buzzing with excitement. With electronics often facing extreme heat and stress, silicone parts deliver durability in spades, enabling designs with precision and resilience that were previously out of reach. Lastly, traditional industrial prototyping can be a slog, dragging time and resources down. But with silicone filament, iterations can be made faster and more cost-effectively, helping ideas evolve from concept to reality in a fraction of the usual time, truly a game changer in the prototyping scene.

The introduction of silicone filament has sparked a creative buzz within the 3D printing community, though not without some skepticism. Enthusiasts are engaged in lively discussions in online forums like Reddit, exploring the possibilities while highlighting potential pitfalls. Many users express a desire for an alternative to TPU yet recognize silicone’s historical adhesion problems. One commenter noted the challenges involved with sterilizing 3D printed objects due to layer lines, a sentiment echoed throughout various threads. “While this could revolutionize silicone’s use, I’m sure it comes with the same issues as 3D printing objects that touch food,” mused one contributor. Community conversations are vibrant with ideas and questions; after all, this is a journey we’re all part of! It’s fascinating to think how these dialogues can shape future practices in printing, leading us towards better solutions.

As silicone filament begins to gain traction, it’s not all smooth sailing. Adhesion issues pose a substantial challenge, requiring users to potentially modify their setups or adopt fresh printing techniques that ensure both stability and quality. Think about it, when you’re learning to ride a bike, you might wobble a bit at first, right? Likewise, silicone requires its users to be patient and persistent. Additionally, the unique properties of silicone mean there’s a learning curve for those used to working with more forgiving materials. Solutions might involve tweaking printer settings, reconfiguring hardware, or even updating software to cater to silicone’s specific requirements. There’s definitely light at the end of the tunnel though; overcoming challenges is part of the fun of the creative process. Just picture mastering this technology and the endless fun of creating astonishing designs.

The introduction of silicone filament is a significant leap in the 3D printing landscape, broadening the horizons of creativity and innovation. As makers navigate this new frontier, I encourage the pursuit of possibilities tempered with a thoughtful approach to addressing the challenges new materials present. Whether you’re an industry expert or a curious newbie, this filament invites you to push the boundaries of your imagination. So, gear up, fire up those printers, and dive into the exciting future that this groundbreaking material unlocks.